Clients &

Industries

Who Are My Clients?

I help big companies to drive outstanding business performance – by using resources wisely, improving their culture and driving positive human impact. I also work with non-business entities such as co-operatives, non-profit organizations and charitable organizations to help them achieve their mandates. By donating my time to projects that have a positive human impact, I subscribe to a ‘blended bottom line’ in my own business model.

Industry Clients

Some of my clients are companies in the mining, automotive manufacturing and management consulting industries, looking to improve their business’ performance and achieve their business goals: in cost, production rates, and quality. With ten years of direct experience putting big results on the table, I am well-positioned to help them achieve these results. I choose projects that not only save money for companies, but also achieve a positive result for their people.

Past projects include reducing safety risk to employees in an operations environment, developing and delivering original training content to improve the efficiency and morale of a manufacturing environment. Besides being good for the business, employees obtain skills and growth opportunities that can serve them beyond the life of the improvement initiative.

Small Business and Non-Profits

I also work with small business owners in diverse areas: community organization, medicine, academia, alternative health. What they have in common is that they all have goals, practices, costs and a larger purpose they desire to achieve.

Whatever field you work in, I can help your business make better decisions with data, process and improvement tools. I love collaborating and helping you succeed. Get in touch with me and let me know how I can help!

Manufacturing

“Deliver value, change the culture along the way.”

You have probably read about how companies like GE, Chevron, Motorola have historically transformed their businesses and profited hugely from adopting Lean or Six Sigma or other process improvement methodologies. I am a Six Sigma Black Belt, which means I have successfully led teams through the DMAIC methodology.

In one of my projects I reduced a particular scrap defect from 5% to less than 1%. In another I reduced the incidence of a Quality issue, saving the company costly containment, sorting and penalty fees. I completed both projects in just under 16 months. Total savings: $350,000.

You have probably read about how companies like GE, Chevron, Motorola have historically transformed their businesses and profited hugely from adopting Lean or Six Sigma or other process improvement methodologies. I am a Six Sigma Black Belt, which means I have successfully led teams through the DMAIC methodology.

Additionally I have coached dozens to save millions of dollars for their companies using Lean in their projects. Therefore I can personally attest to Lean and Six Sigma’s ability to deliver significant improvements in operating costs, quality performance, customer satisfaction, worker safety and morale.

By uncovering the true Costs Of Poor Quality (COPQ) and then harnessing the problem-solving power of your cross-functional teams, you can isolate and eliminate the root causes of missed deliveries, customer quality rejects, equipment breakdown, internal scrap and other headaches. With steady application of the improvement principles and the support of operational leadership (that’s you!), Lean and Six Sigma can improve transform your shopfloor’s operations and in turn, your business’ success.

We both know there’s no such thing as a silver bullet. When adopting any improvement program it’s important to have someone who has experience beyond the buzzwords, and the ability to pick the right tool, not just following a rulebook. Because I have been there, and because my clients’ success is my success too, I will set you up to succeed with a detailed, realistic Improvement Plan.

Kicking off a new improvement initiative can be daunting and the fact is that significant improvement does not happen overnight. However there are nearly always quick wins (or low-hanging fruit) that can give you a return on your investment very quickly. Once your Improvement Plan begins to deliver results, it will energize you and your workforce toward finding more. That’s when things get really interesting – and fun!

My experience in Root Cause Analysis, Errorproofing, Employee Engagement and many other tools will help me guide your team toward solutions that works and keeps working for your operations environment.

So no matter whether you are running already running at a Four or Five Sigma level, or just beginning on your improvement journey, I would be happy to work with you to identify your best improvement opportunities, and develop a strategy to capture them. Give me a call today so I can hear more about how I can help you to transform your shop floor using Six Sigma or Lean methods!

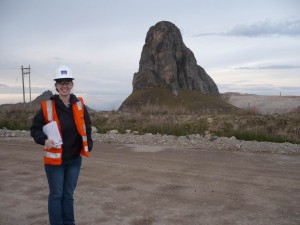

Mining

“Deliver value, change the culture along the way.”

Since process improvement methods like Six Sigma and Lean originated in the manufacturing industry, it might seem odd to apply those methods to your mining operations. However, top companies like BHP Biliton, GoldCorp, Barrick and Rio Tinto have achieved huge savings by doing just that.

How? A few of the projects with which I myself have been involved: augmenting life of tires on haul trucks, standardizing and organizing blast inventories, improving blast efficiencies, analyzing ore throughput, optimizing leach pad parameters to improve recovery.

We did it using the same principles that Lean manufacturing companies have used for years to remove waste, engage their employees’ know-how, and identify and capture opportunities for improvement. You know your business and your mining processes; I know the tools that can help you shape that knowledge into significant savings and an improved working environment.

As a former Continuous Improvement Coach for one of the largest companies in the world, I have a proven track record of training and mentoring Mining Maintenances Mechanics, Technicians, Mining Engineers and Mining Admin/Support staff to use problem-solving tools and think Lean – and uncovered millions of dollars in value creation opportunities.

We both know there’s no such thing as a silver bullet. When adopting any improvement program it’s important to have someone who has experience beyond the buzzwords, and the ability to pick the right tool, not just following a rulebook. Because I have been there, and because my clients’ success is my success too, I will set you up to succeed with a detailed, realistic Improvement Plan.

Kicking off a new improvement initiative can be daunting and the fact is that significant improvement does not happen overnight. However there are nearly always quick wins (or low-hanging fruit) that can give you a return on your investment very quickly.

So no matter whether you are skeptical about improvement programs or already successfully using Lean and Six Sigma process improvement strategies in your business, I would be happy to help you identify your best improvement opportunities, and develop a strategy to capture them.

Give me a call today so I can hear more about how I can help you improve your mining operations – from the ground up!

Professional Services

“Deliver value, change the culture along the way.”

You want to provide the best possible experience for your customers when you sell them your services. You need to do it within budget, to a high quality standard, while maintaining a positive and energizing culture for your team. I’ve helped many service-based firms develop standardized processes to take the guesswork out of training their people, and establish measurable targets for improvement and then drive toward them. I’ve also helped them uncover key insights in how to create a super-charged team environment that has everything the business magazines are talking about. Leadership drives great results, and innovation thrives when you have a truly inclusive and respectful workplace. I can help you take these big concepts and distill them into achievable tasks and steps that will really add up for your business — today and down the road.

Safety

Focused results based on strategy and reality.

What we do prioritizes the well-being of employees of our clients over other business imperatives such as productivity and profit; this includes physical safety (an environment that measures and incents few injuries and incidents), psychological safety (an environment that values its people’s ideas and voices, creates opportunities for them to contribute, and encourages people to report and reflect on mistakes and problems, for example) and financial safety (a company that prioritizes preserving jobs even in tough economic conditions, and ideally provides employees with a share in the success of the company in the form of profit-sharing).

- Missed production targets

- Spiraling operations costs

- Standards aren’t being followed

- Disengaged / unmotivated front lines

- Establishing support from Corporate

- Mergers, acquisitions and reorgs

- High turnover and fire-fighting

Executive Team

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

About Us

Learn how to get the most of the tax system for both corporate and individual income.

Story of our Company

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

With all this competition, simply creating a better product and creating a marketing campaign is no guarantee that you will stand out.

Executive Team

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

We advise global leaders on their most critical issues and opportunities.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur